Application note

Introduction

In this project a KNF FMM-20 dosing pump was used to dispense droplets with a size of 4 to 18 microliters. Its stroke was adjusted by a servo motor to variate the volume. For a control loop the Pulsed Flow Sensor (PFS-V3) was used as a reference.

Used Material

+ Pulsed Flow Sensor

+ PFS controller

+ KNF FMM-20 pump

+ Mettler AT 261 balance

+ Servo for stroke adjustment

+ Water container

+ PVDF 1/8" Tubing

Experiment setup

The Pulsed Flow Sensor was connected to the aspiration side of the pump. In a vertical setup, single droplets were dispensed at a frequency of 1Hz. The tube between sensor and pump was kept as short as possible to prevent damping.

Stroke and droplet Volume

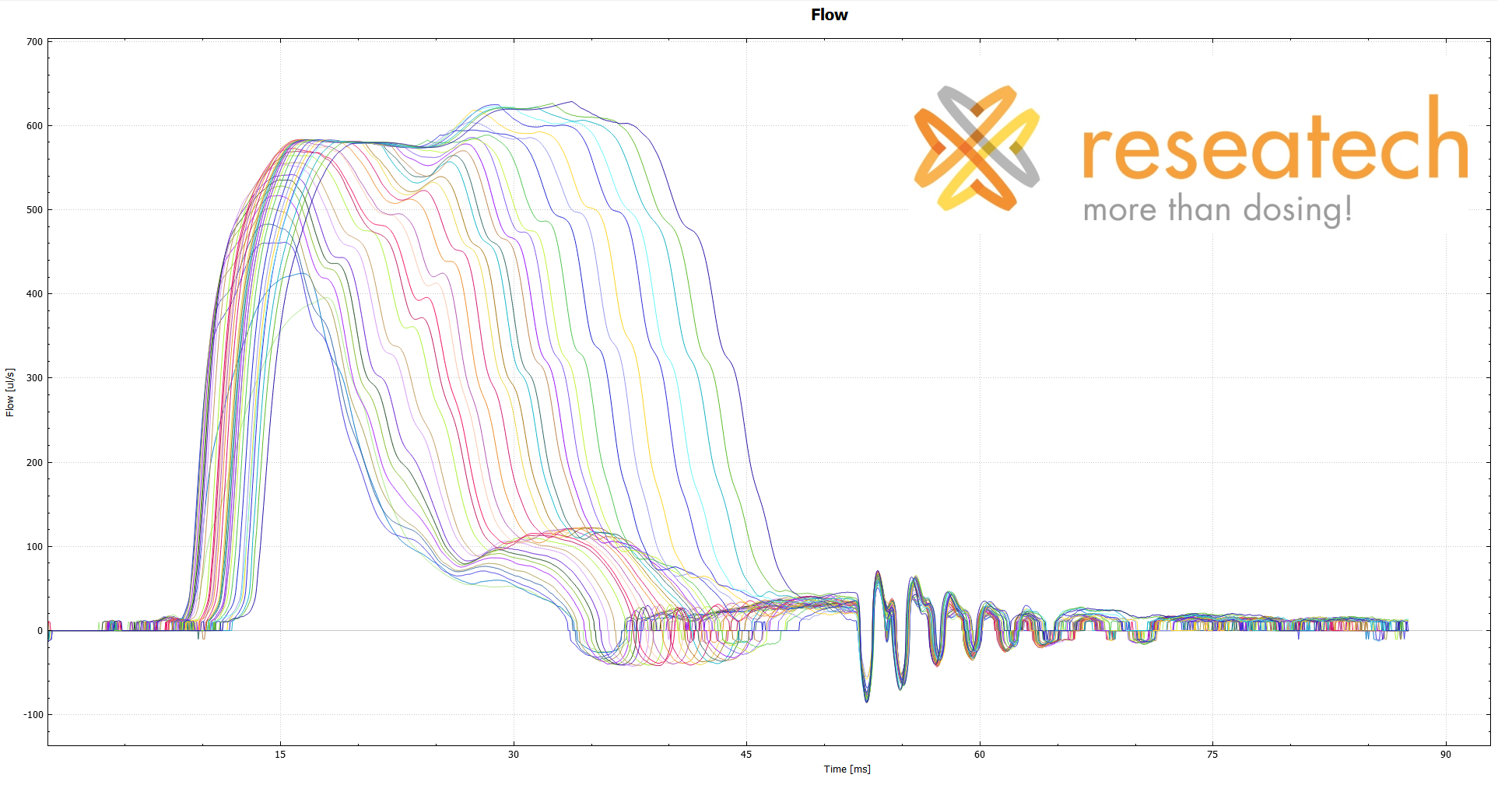

The stroke of the FMM-20 pump is varied by turning an adjustment screw from 0 to 100°, while in figure 1, 100° is the minimal stroke and 0 the full stroke height of the pumps plunger.

Measurements

For 35 different plunger strokes, the droplet volumes were recorded by the Pulsed Flow Sensor at a sampling rate of 20 kHz.

The data shows:

+ Small plunger strokes show an earlier raise in flow than big plunger strokes.

+ Big plunger strokes show a plateau and an acceleration before closing.

+ The closing event at 50 ms and the post-pulse oscillation is very reproducible.

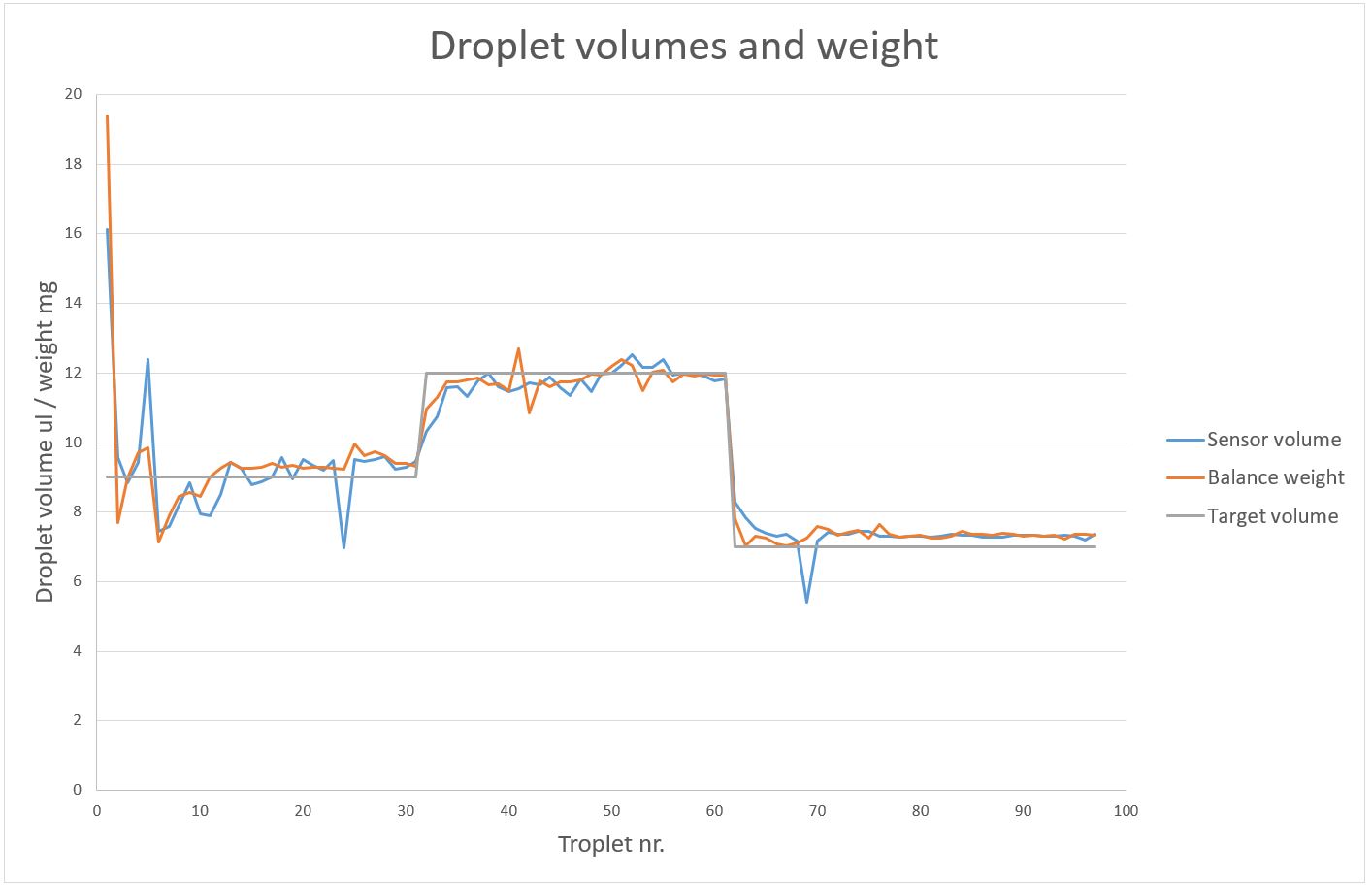

Implementing a control circuit

With a PID control loop the droplet volume was guided to follow a Target volume of 0, 12 and 7 microliters per shot. The flow sensor signal was used as the control variable. As a second reference, a balance measured the droplet volumes.