APPLICATION NOTE

Flow measurement of H2O2

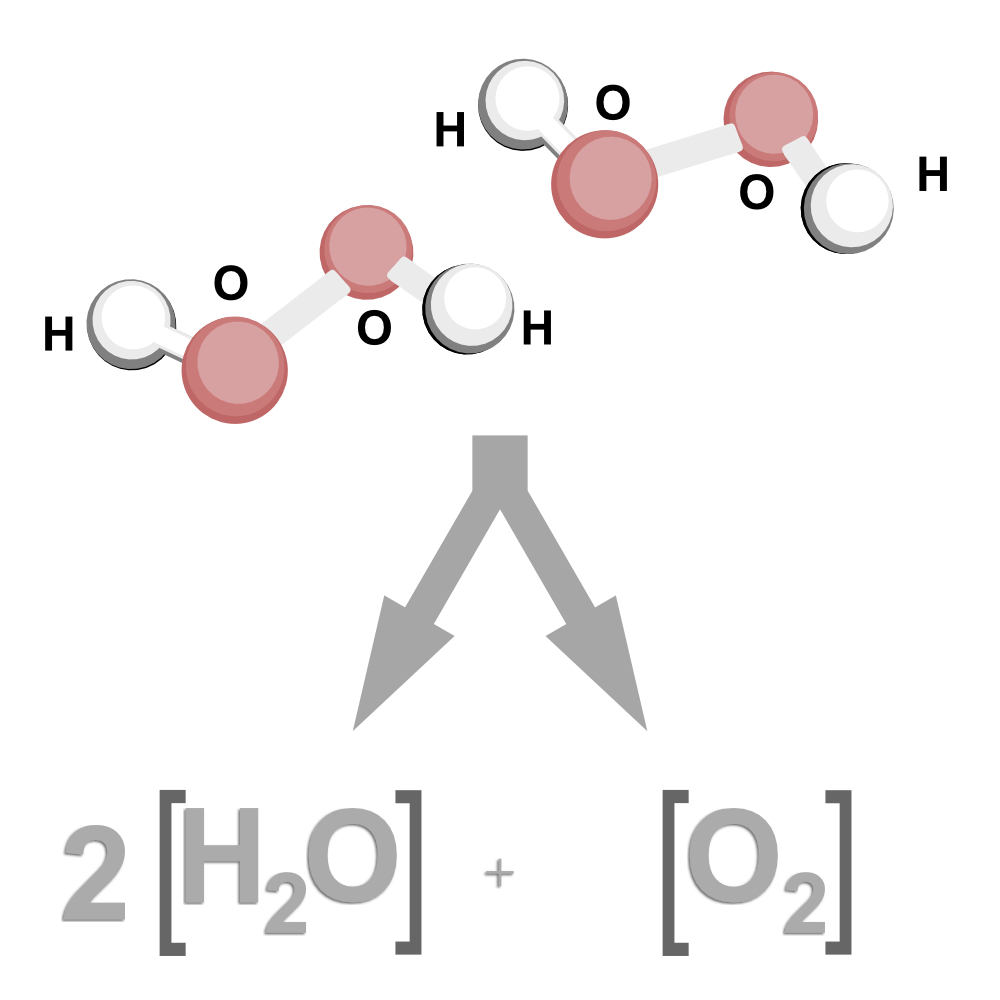

Nowadays hydrogen peroxide is dosed in many applications. The strong oxidizing agent with the chemical formula H2O2 kills bacteria and viruses and decomposes to harmless oxygen and water. Especially in times of COVID-19 hydrogen peroxide and its correct dosage is in great demand.

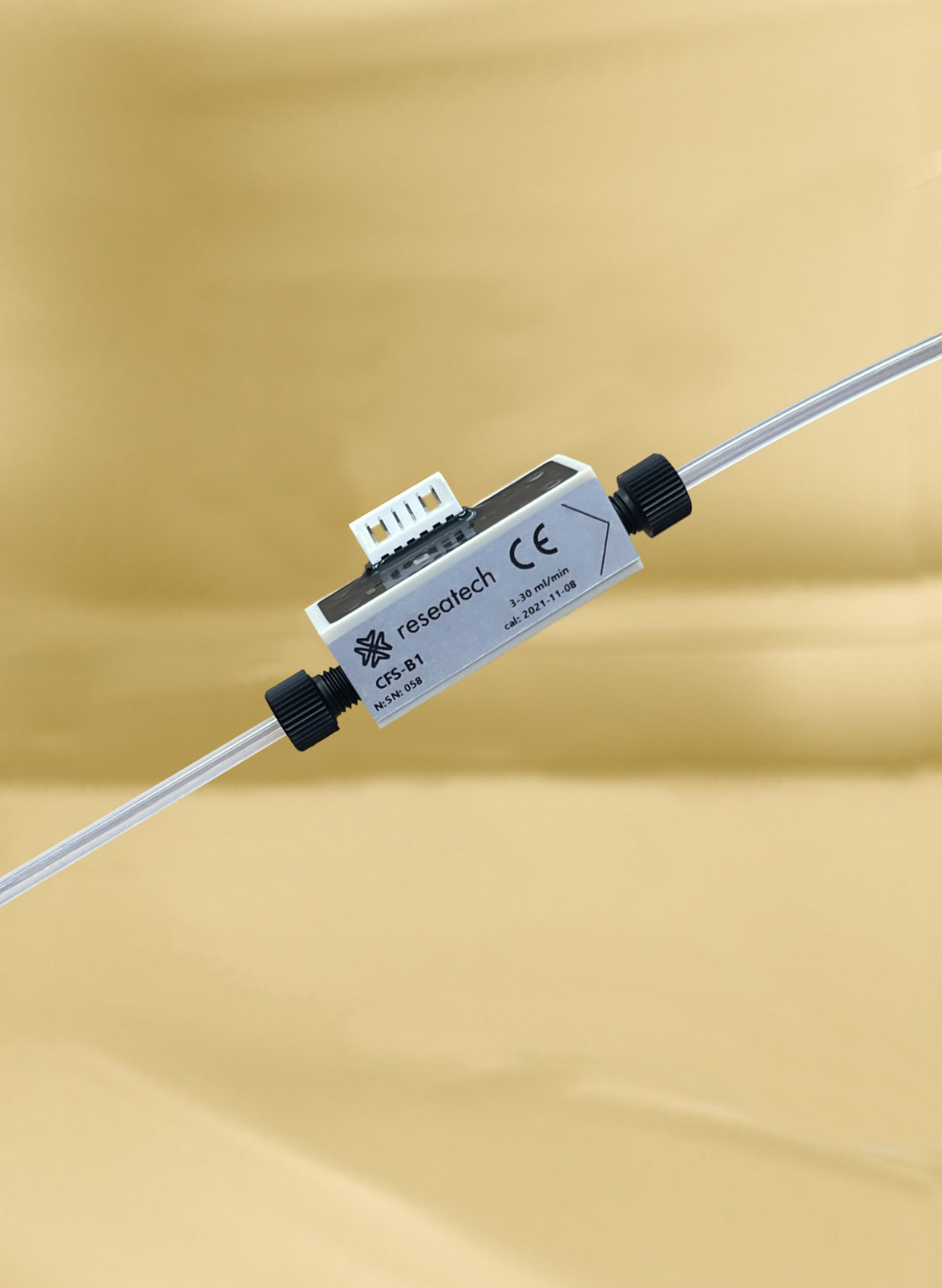

The sterilizing agent H2O2 is distributed in many devices by a spray nozzle in the room. The Continuous Flow Sensor (CFS) is particularly suitable for measuring the dosed flow rate of hydrogen peroxide.

Unsusceptible to gas bubbles

At room temperature, H2O2 gradually decomposes into O2 and water, outgassing oxygen bubbles. Due to the differential pressure measuring principle, the CFS reacts quickly to such gas bubbles and does not take them into account in the measurement. This is possible because the sensor has a fast response time of only 10 milliseconds and no overshoot effects in case of large flow rate changes.

Volume measurement

The user is less interested in the flow of H2O2 and more in the total dosed quantity. However, due to gas bubbles in the hoses and containers, dosing devices such as pumps cannot guarantee reliable quantities and therefore need the monitoring of a sensor.

To avoid too much flow data, the readout interval for the CFS can be reduced to up to 1 signal per minute. However, this does not impair the fast scanning and detection of gas bubbles, but it does make the measurement of a total volume much easier.

Calibration for H2O2

Hydrogen peroxide is often used in concentrations of 10 - 50 %. This changes the physical properties of the mixture (viscosity and density). Does the CFS always have to be calibrated to the medium?

The handling of these fluid properties of H2O2 is very simple: With the CFS, the density and viscosity of the hydrogen peroxide can be easily programmed by the user. These data are usually taken from the safety data sheet of the H2O2 product used or from a table.