What is a micro dispensing valve?

A micro valve for dispensing applications is an electromagnetic 2/2-way valve with a built-in dispensing nozzle (also called jetting valve). It can shoot fast droplets and works similar to an electronically controlled water tap, just a lot smaller.

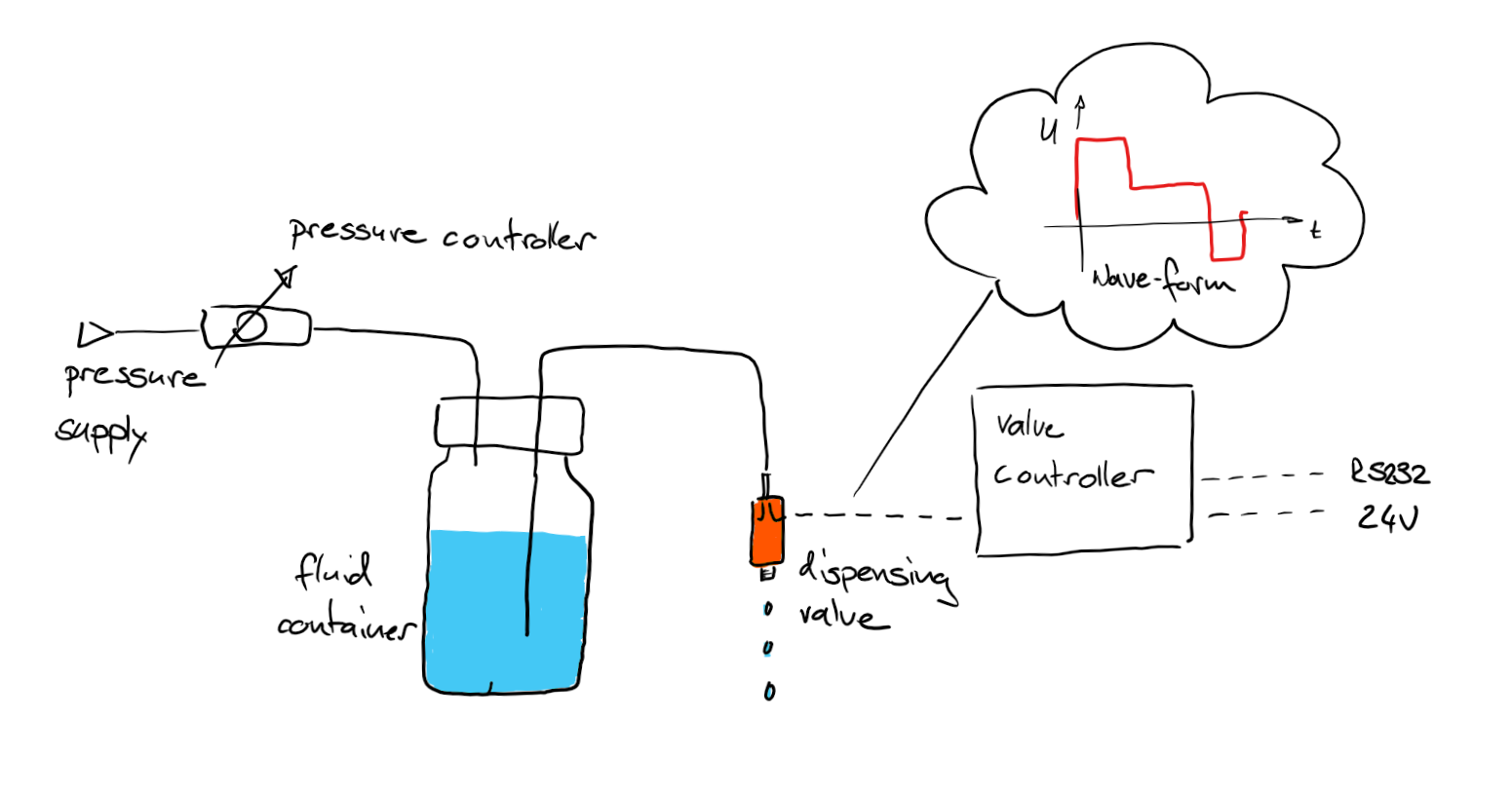

Time-Pressure dispensing

To dispense a liquid droplet with a dispensing valve, a pressurized fluid container is needed. The pressure inside this tank forces the fluid to the valve. An electric signal opens and closes the valve to dispense small volumes of liquid.

In the specific case of a micro dispensing valve, the opening times have to be only a few milliseconds in order to dispense very small droplets.

Short valve switching times

A micro valve is built with a strong magnetic coil and a very small and light moving plunger or membrane. Combined with a short plunger stroke, this leads to very short switching times that make micro dispensing possible. In the example of the B-drop mini, the switching only takes 0.3 milliseconds.

“small” Volumes

On the upper end, a micro valve dispenses a continuous flow of about 5 to 50 ml/min. But how low can a volume dispensed by a micro valve go? This question depends on many factors. With low viscous media like water and using the right fluid pressure and waveform, a Micro valve an dispense as little as 10 nanoliters in a droplet. However the accuracy of such a small droplet may be poor. If even smaller droplets in the picoliter area are needed, a piezo driven inkjet system ist oftentimes used.

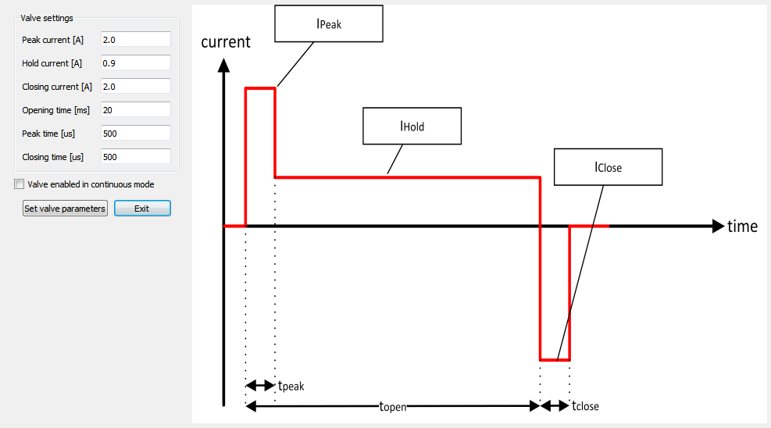

Controlling a micro valve

An electromagnetic micro valve is usually controlled by a valve controller. The valve controller is able to set the valve opening time with a microsecond resolution. Further it supports a reduction of the current to prevent the valve from overheating. This mode is called a Peak-and-hold waveform. In the specific case of the ReseaTech Valve controller it can even switch the electrical polarity to actively close the valve. The controller has a trigger input to synchronize the dispensing with a moving axis of for instance a printer or an automatic dispenser.

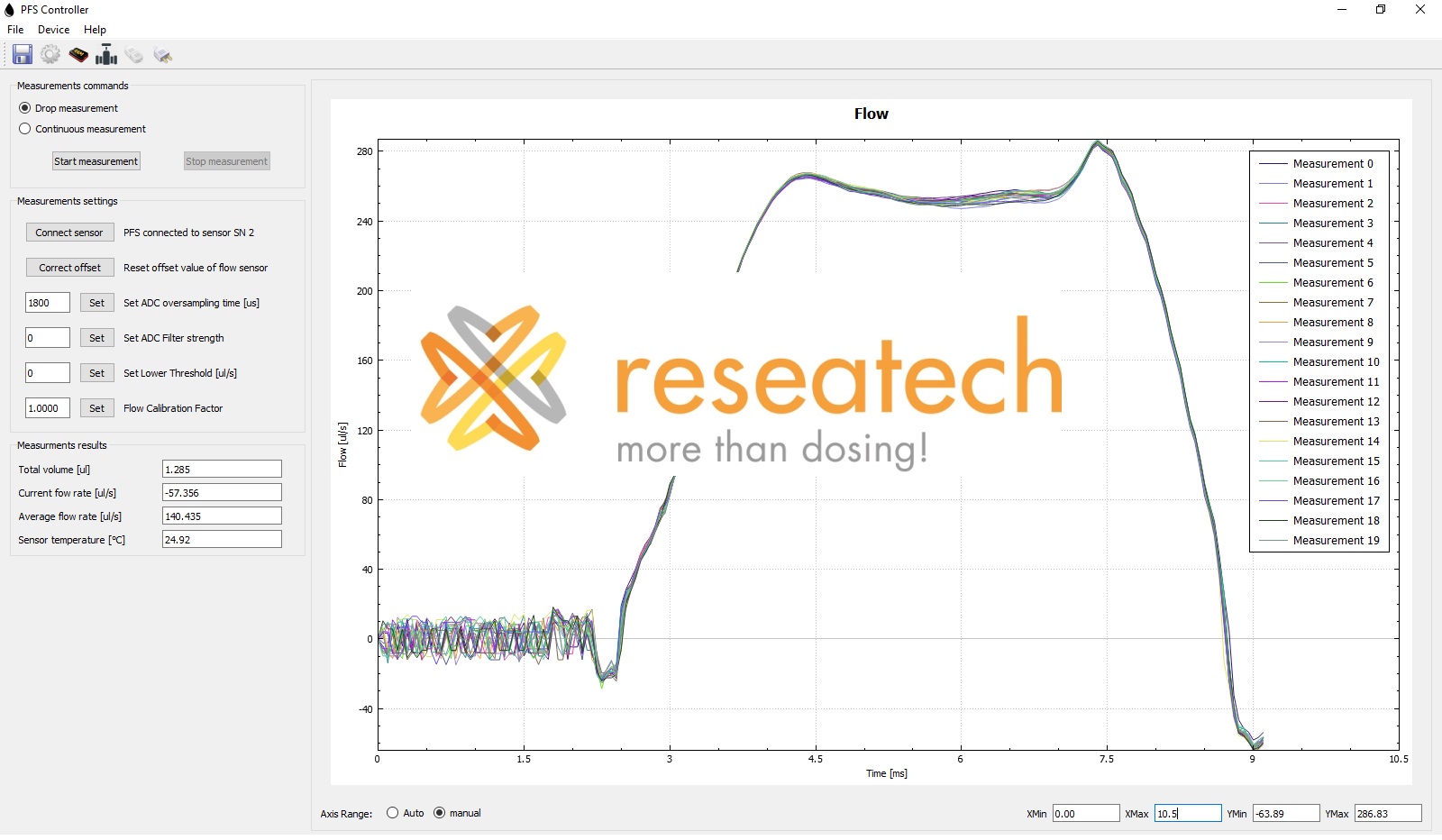

Measuring the droplet size

Droplets dispensed by a micro valve can be measured in various ways. The most common way to achieve reliable dosing volumes is weighing the droplets on a highly accurate balance for calibration. However, this process requires that the fluid pressure and temperature is held constant over the whole dispensing process.

An alternative that is provided by ReseaTech, is the inline measurement of droplets using a very responsive flow sensor (the Puled Flow Sensor). Using this technology, all dispensed droplets can be protocolled during the dispensing operations.