Differential-pressure flow sensor

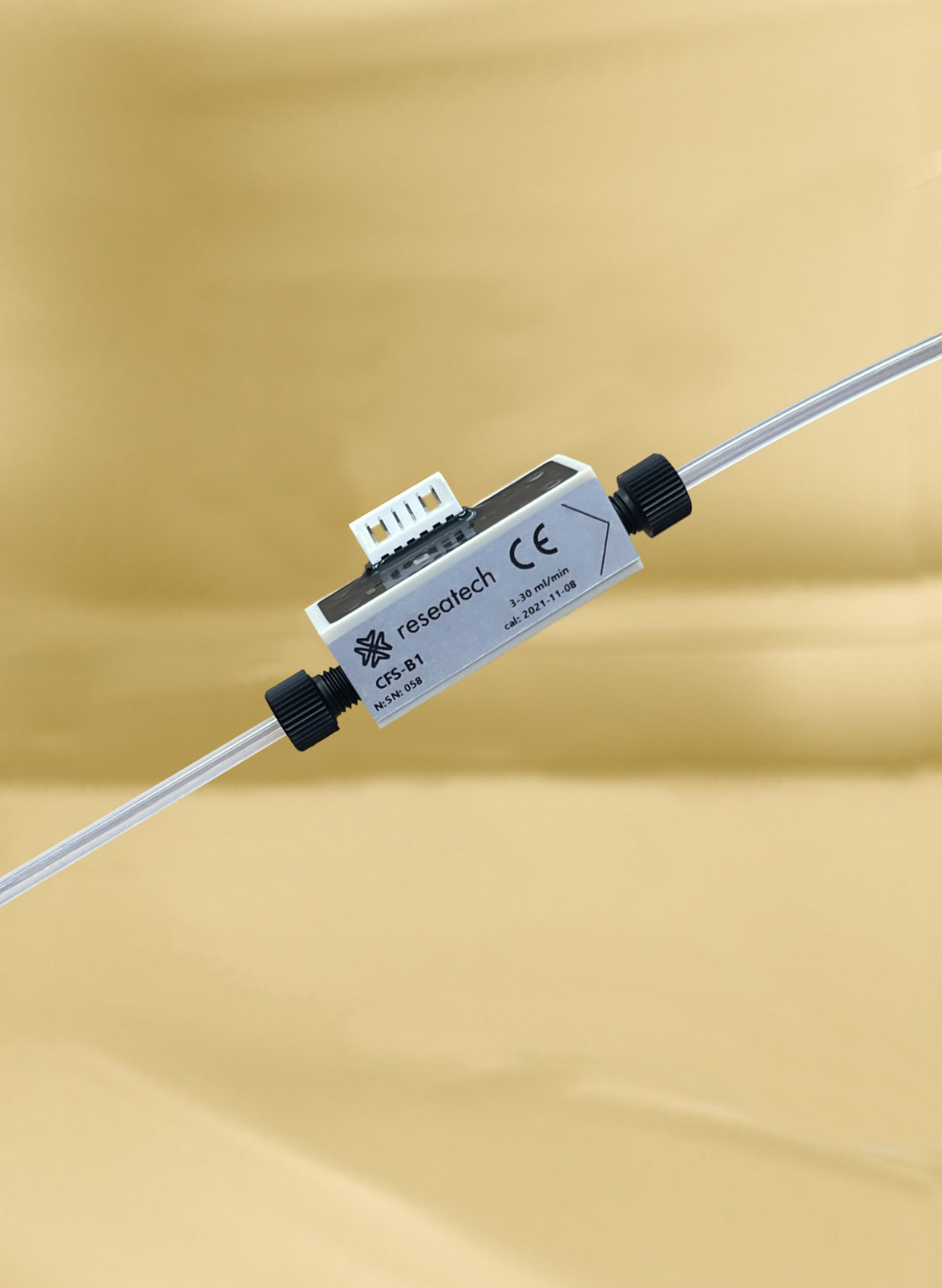

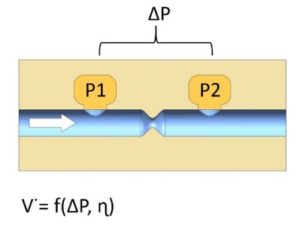

The Pulsed Flow Sensor (PFS) is a small volume flow sensor, based on the elementary principle of a pressure drop over a restrictor in the flow channel. Between two pressure sensors a circular aperture produces a pressure loss. A major advantage of this principle is, that combined with fast-reacting pressure sensors it has a very short response time of about 1 millisecond. This enables the volume measurement of Droplets smaller than 1 Microliter.

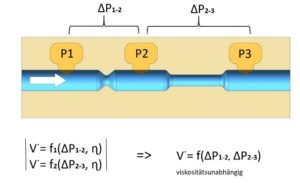

Viscosity compensation

The PFS further uses friction to determine the fluids viscosity. With this additional information the sensor electronics are capable of measuring a viscosity-independent volume flow. This means that the fluids viscosity properties do not have to be known, neither calibrated to obtain an accurate volume flow measurement. The PFS micro flow sensor can mesure one- or bidirectional (depending on the version). Because of the PFSs short reaction time, it is able to detect very quick changes in the volume flow, such as an opening of a valve.

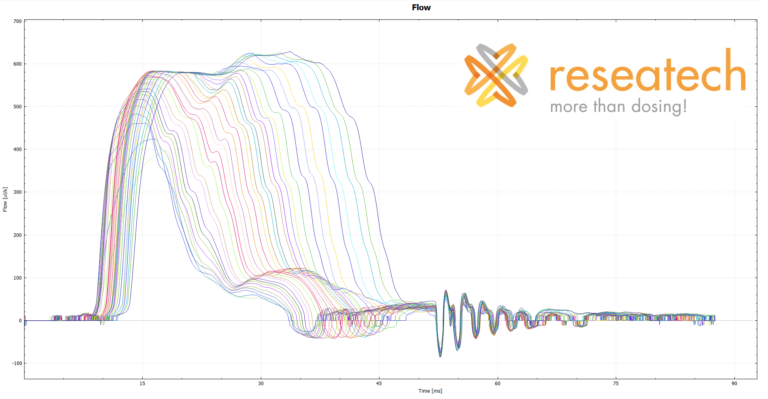

Droplet measurement

This micro flow sensor has been initially developed to measure the flow through a micro dispensing valve. Micro dispensing valves usually use pressurized fluid from a reservoir and they are activated by an electromagnetic coil. Because micro valves have very short opening times of only a few milliseconds, the flow sensor needs to have a very short reaction time and high sampling rate of 20 kHz, to be able to capture this event properly.

Volume Integrals

The Pulsed Flow Sensor was designed to measure volume flows that take microseconds to minutes. It can automatically Integrate the volume flow to determine the processed volume from a dispensing or sampling process.

Pulsating pumps

Because the Pulsed Flow Sensor is capable of measuring strong fluctuating flow, it can be used to monitor the flow of pulsating pumps. For pump manufacturers the pulse form can be measured to optimize the pumping performance of their product. In other applications the volume flow of the pump just has to be measured to control the process.

PFS – Pulsed Flow Sensor

The Pulsed Flow Sensor is a very dynamic volume flow sensor for liquids. It was developed to monitor the flow of pulsating pumps and fast switching valves. This reliable and chemically resistant sensor enables you to measure sharp volume integrals and therewith monitor and control every dosing proce…